Production process

Preparation

The loess clay is gathered from the company’s pit. The raw material is volumetrically premixed.

A variety of recipes create differing results in colour, pattern, texture and quality of the finished bricks.

Conveyors deliver the pre-mixed clay into the edge mill. This can be likened to a gigantic coffee mill.

Through edge runners the clay gets crushed, crumpled and ground. This is the first step of the clay’s homogenization.

After the homogenization process, water is added to achieve the desired level of moisture. The, now, fully prepared clay goes into one of the two shaping plants.

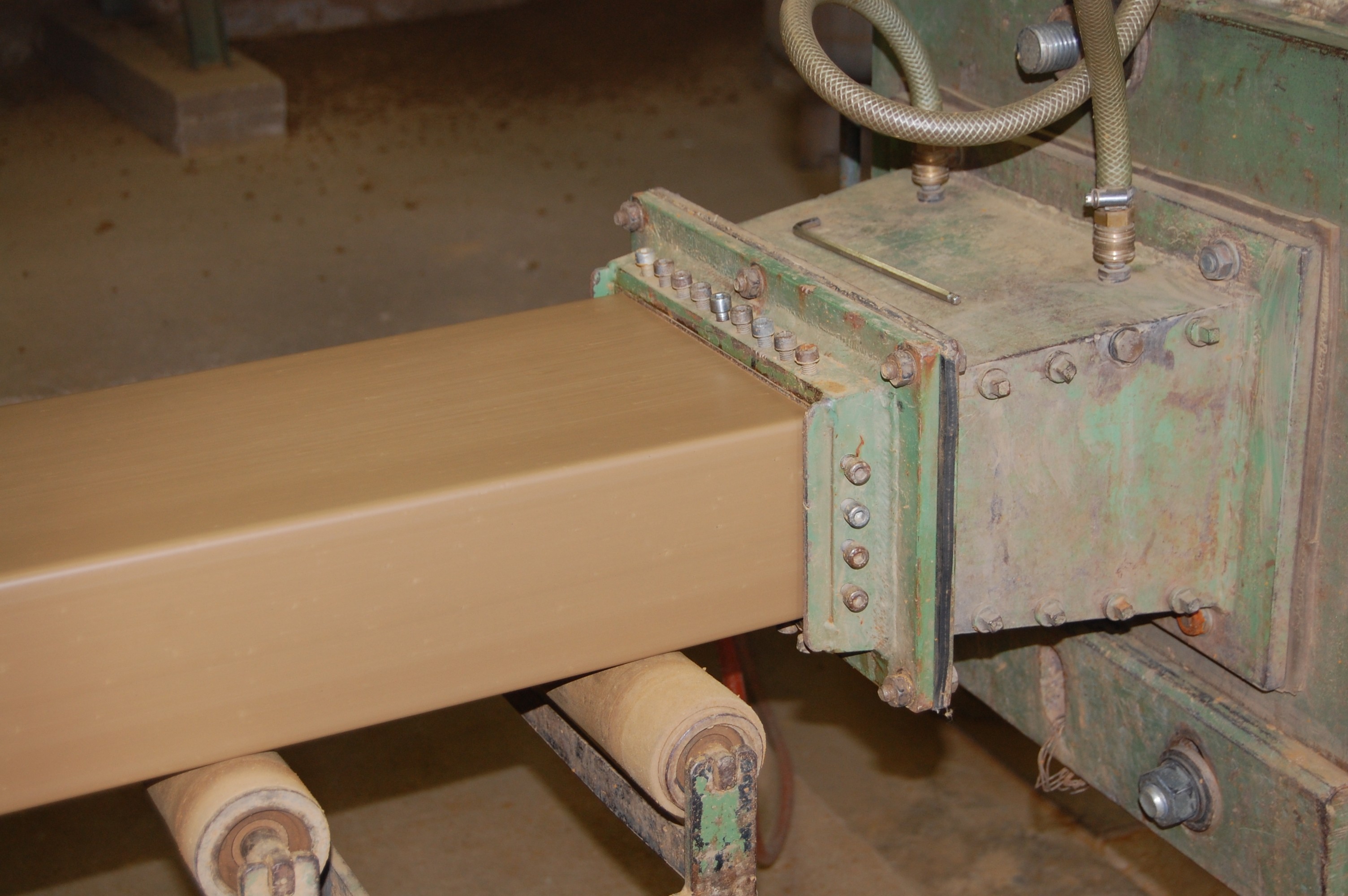

Vacuum extrusion press

Under high pressure, the clay thread is getting pressed out of the tip of the machine. Its important that all parameters are well coordinated.

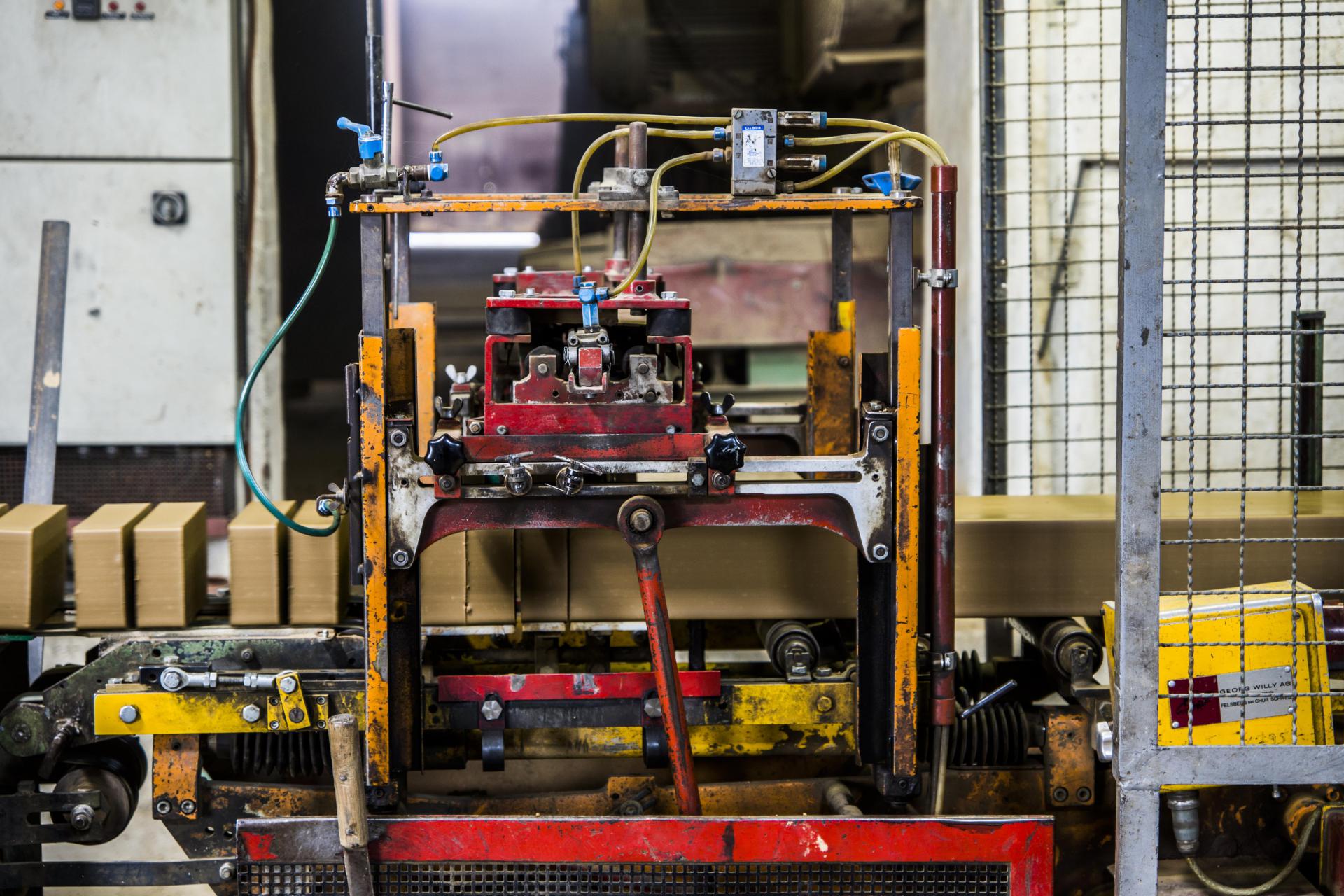

The Cutter cuts the single pieces out of the clay thread.

The raw clay bricks are now ready for the rest of the production. The last step before the pieces will be burned, is the withdrawel of any humidity in a drying chamber.

After the dried blanks are put in the kiln, according to a specific pattern thats known by our experienced coworkers, the kiln master closes up the ring kiln.

Following our various burning rituals, that have been undergoing improvements over 100 years, the kiln master watches over the burning of the bricks.

The final step is to get the clinker bricks out of the kiln. This is, again, done by hand, which means that every brick undergoes various quality controls.