Joints

Adhesives: There are plenty of different tiling adhesives on the market.

Three things to consider with regard to grouting are:

- the correct technical execution

- the appropriate grouting method

- the right jointing mortar

(see also DIN 1053)

1. Optimal grouting conditions

Directly after finishing grouting the masonry should get covered up with a plastic sheet (or something comparable). It’s necessary to protect the masonry from weather impact so the freshly applied jointing mortar won’t be contaminated or washed out. This means grouting work must be carefully planned and protected during bad weather. If it’s not possible to protect the grout from bad weather the project should be postponed. Extreme temperatures can also be detrimental during the curing process. Extreme heat can lead to ‘burning’ on the joints and severe frost can cause joints to crack. Consequently, it is very important to wait for the right weather conditions before starting to grout.

2. Appropriate grouting method

The most suitable grouting method for a particular job should be determined by the type of brick chosen. If the owner or the jointing mortar expert are unsure which process to use the clinker brick producers should get questioned.

The most common grouting methods are:

- Smoothed joints / pointing : In this process, masonry mortar will be used as jointing mortar. To avoid air pockets during the grouting process, superfluous grout that sits proud of the bricks should be smoothed out evenly with the correct, or a lighter, jointing tool. This technique reduces air pockets and creates a neater finish. The fresh mortar must be cleaned off the masonry right away.

- Belated grouting: If subsequent grouting is wanted or deemed necessary, dry mortar should be used. Dry mortar can be bought as a finished mixture. Firstly, using jointing tools, fill horizontal joints with a tilting adhesive. Afterwards address vertical butt joints. We advise using dry mortar for any subsequent jointing procedures when working with Gillrath bricks.

3. The right jointing mortar

It is imperative to use the right type of jointing mortar. Failure to do so can result in major detrimental consequences, such as efflorescence. The DIN 1035 determines which mortar sortiment to use for the exposed masonry. We advise remixed, dry mortar containing a low salinity.

( Mortar sortiment II or. II a) (Examples include Sakret, Quick Mix and more). We also strongly advise against trass-based cement.

(see also: www.ziegel.de)

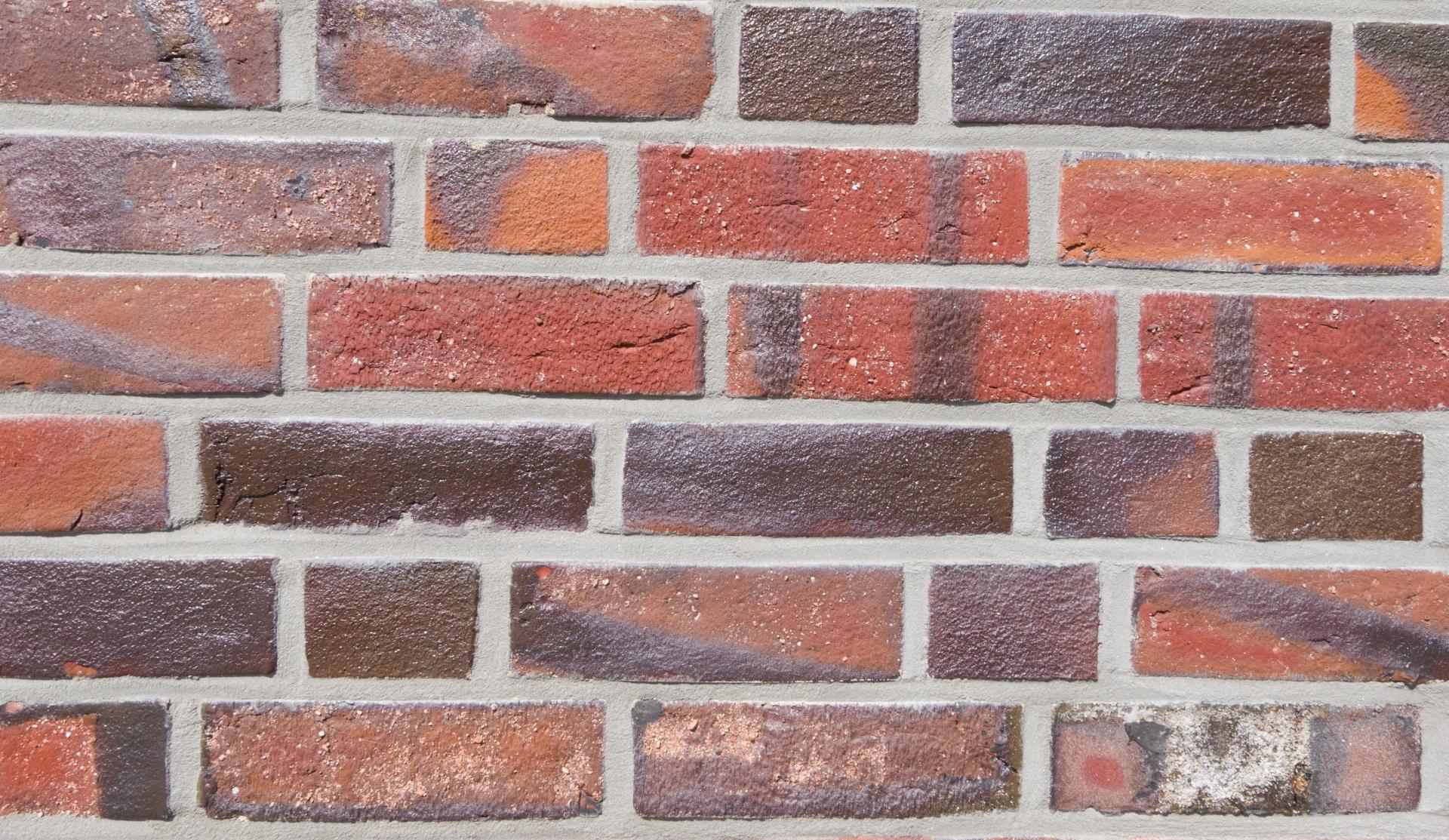

Dark grey and anthracite coloured joints emphasize the colour diversity of clinker-bricks and cause greater effect dimensionally.

Cement grey colored bricks look less dimensional and are more calming.

Adhesives: There are plenty of different tiling adhesives on the market.

Three things to consider with regard to grouting are:

- the correct technical execution

- the appropriate grouting method

- the right jointing mortar

(see also DIN 1053)

1. Optimal grouting conditions

Directly after finishing grouting the masonry should get covered up with a plastic sheet (or something comparable). It’s necessary to protect the masonry from weather impact so the freshly applied jointing mortar won’t be contaminated or washed out. This means grouting work must be carefully planned and protected during bad weather. If it’s not possible to protect the grout from bad weather the project should be postponed. Extreme temperatures can also be detrimental during the curing process. Extreme heat can lead to ‘burning’ on the joints and severe frost can cause joints to crack. Consequently, it is very important to wait for the right weather conditions before starting to grout.

2. Appropriate grouting method

The most suitable grouting method for a particular job should be determined by the type of brick chosen. If the owner or the jointing mortar expert are unsure which process to use the clinker brick producers should get questioned.

The most common grouting methods are:

- Smoothed joints / pointing : In this process, masonry mortar will be used as jointing mortar. To avoid air pockets during the grouting process, superfluous grout that sits proud of the bricks should be smoothed out evenly with the correct, or a lighter, jointing tool. This technique reduces air pockets and creates a neater finish. The fresh mortar must be cleaned off the masonry right away.

- Belated grouting: If subsequent grouting is wanted or deemed necessary, dry mortar should be used. Dry mortar can be bought as a finished mixture. Firstly, using jointing tools, fill horizontal joints with a tilting adhesive. Afterwards address vertical butt joints. We advise using dry mortar for any subsequent jointing procedures when working with Gillrath bricks.

3. The right jointing mortar

It is imperative to use the right type of jointing mortar. Failure to do so can result in major detrimental consequences, such as efflorescence. The DIN 1035 determines which mortar sortiment to use for the exposed masonry. We advise remixed, dry mortar containing a low salinity.

( Mortar sortiment II or. II a) (Examples include Sakret, Quick Mix and more). We also strongly advise against trass-based cement.

(see also: www.ziegel.de)

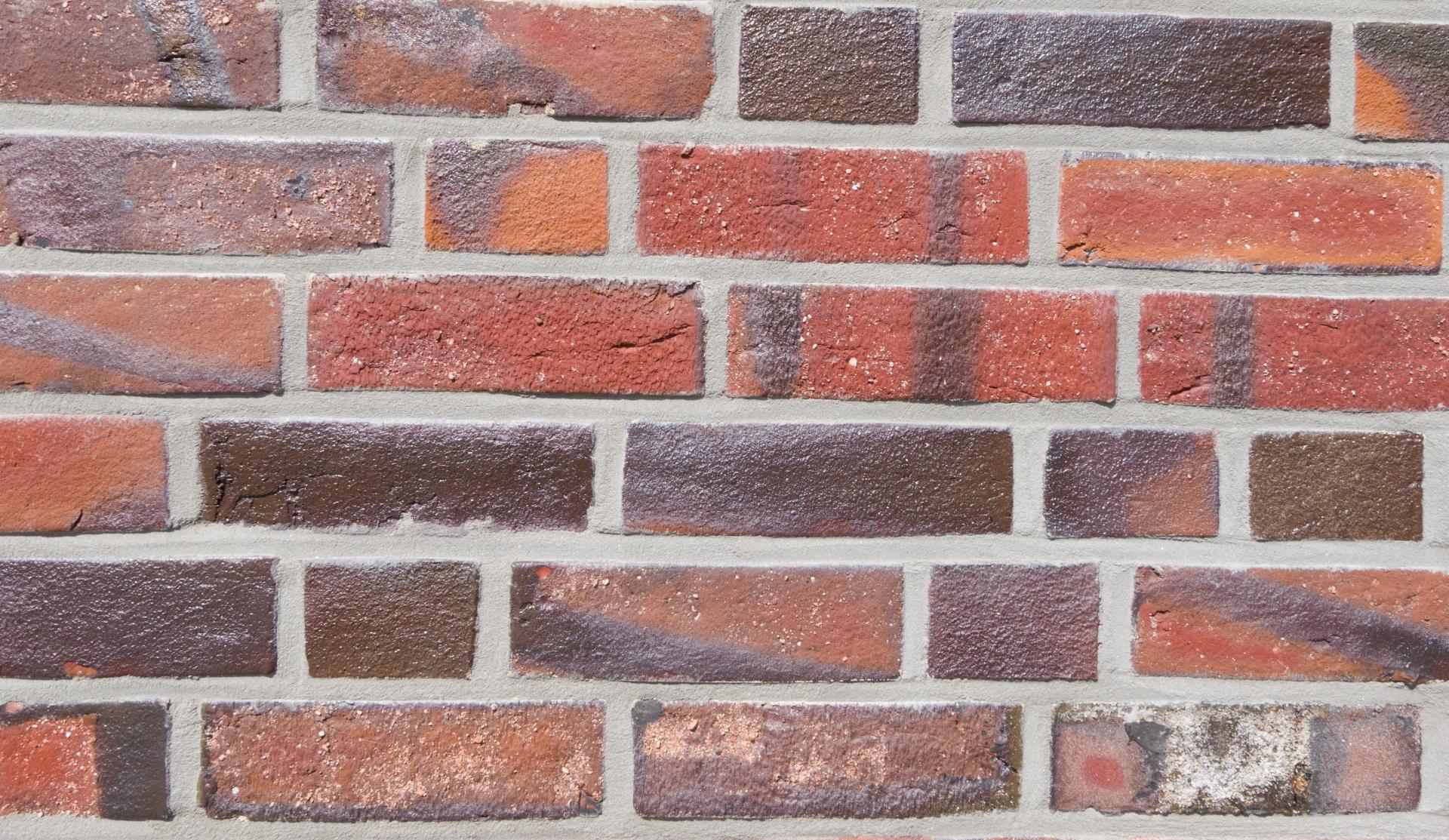

Dark grey and anthracite coloured joints emphasize the colour diversity of clinker-bricks and cause greater effect dimensionally.

Cement grey colored bricks look less dimensional and are more calming.